What is our innovation all about?

Our activated carbon filter is the perfect solution for drivers who want to feel better about their carbon footprint, even if they own cars that may contribute to global warming in negative ways. This filter is optimal for consumers who live in less developed countries (often countries where non-renewable fuels are more prevalent, such as India) or who simply want to reduce the environmental impacts of driving their vehicles. The installation of The Green Mile’s device significantly reduces the amount of harmful emissions released into the air. Plus, with its easy installation and low maintenance requirements, anybody can enjoy the benefits of this filter without any hassle. Not only does this safeguard the environment, but widespread adoption could mean significant reductions in country CO2 emissions, contributing towards their goals and pledges made at the Paris Climate Conference and at COP27 (1).

How did our team form?

We all studied at the same educational institution and found ourselves with similar perspectives on many aspects of our systems. As Aryan migrated into America, we chose to continue working with him while remaining cognizant of the geographical difficulties we might encounter. We felt that our geographical differences could be used to our advantage as we could explore different types of markets and research two completely different consumer landscapes (something which we did!). Svanik Garg plays the role of the scientific spearhead of the innovation (aspects such as design engineering, research, CAD etc.), Krishay Sutodia plays the role of having generalised knowledge in both scientific research and economics and Aryan Baruah plays the role of having knowledge regarding the consumer and business side of the innovation, knowledge of supply and demand side economics and limited scientific knowledge.

Which issue does our innovation strictly address?

Climate Change and particularly global warming poses a humongous problem to the well-being of the Earth and all those who reside on it. One of the main contributors to GHG is the carbon offset that came with the ideological developments in the concluding stages of the Modernist Era and the preceding Industrialization. This has only exponentially increased over the previous decades and has resulted in regions (particularly the Global South) feeling the harsher effects of worldwide economic prosperity. One of the main sources of carbon emissions is transportation, an area that accounts for 15% of global emissions (2). Out of this 15%, passenger vehicles account for 41%. That basically means that passenger vehicles account for 6.15% of total global emissions, not an inconsequential amount (2)! It would be difficult to find a household that doesn’t have at least one car in its garage, and while large-scale electric vehicle manufacturers such as Tesla are helping to reduce these numbers, it is barely making a dent. A few barriers to Tesla reaching a scale where its impact can be felt on a global level is the fact that Tesla isn’t global. While this may seem like a trivial statement, the reasons for it act as a leading point for why our innovation is necessary. Deeply ingrained cultural norms in developing and underdeveloped countries, (countries who are projected to produce the most CO2 emissions in the upcoming years due to the fact that they are undergoing their process of modernization), combined with the overall cost of electric

vehicles makes them less desirable, even to consumers who may want to positively impact the environment. Allowing and capitalising on those consumers by offering them an attachment that is cost effective and simplistic such as ours would significantly increase our potential in the fight against global warming.

What is our innovation: its design, its technology and the method by which it functions?

The Green Mile is a revolutionary concept, ideated with the thought of accelerating a greener future, often hindered by resistance to change. The innovative concept associated with this product is eliminating the net emissions of a car engine right at its exhaust. The idea is to avoid expensive carbon recapturing methods, or adjusting combustion engines, both of which prove to be expensive.

The exhaust of a motor vehicle is a complex mixture of gases, vapours, aerosols, and particulate substances. The exact nature of the exhaust depends on a number of factors including the type of engine, how well serviced/maintained the engine is, type of fuel, type of oil, speed and load on the engine. There are three different classes of pollutants that stand out: soot, carbon dioxide and other micropollutants (see [1]). The Green Mile’s objective is to fit filters capable of eliminating these pollutants, and clean the atmosphere with an expected 80-83% efficiency (calculated using CFD particulate analysis on blender) based on particle load of the exhaust released by the car.)

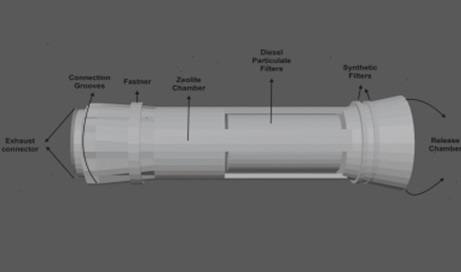

The base design is a 11.25 inch structure shaped as a modified tube, with the following filters serving the ultimate purpose of reducing emissions:

Synthetic air filters made of polyester and synthetic fibres will be designed to trap microparticles and fine debris. They are less expensive than other types of air filters, and are less likely to become clogged with debris over time, making them ideal for the Green Mile.

Diesel particulate filters (DPFs) will be used to remove unreacted carbon/soot from the initial exhaust before it is released into the atmosphere. Our chosen DPFs work by using a filtering media to capture the soot particles from the exhaust gas. The filters will be made of ceramic

and widely available metallic materials to avoid extra costs. Over time, the soot particles tend to build up, however our product is designed to be regenerated periodically through the use of heat generated by the vehicle’s engine.

Zeolite is a material that can absorb a gas and hold it within its pores. This makes it useful for removing CO2 from gas streams; in our case, those produced by vehicle exhausts. Zeolites’ porous structure makes it possible to “sieve” CO2 molecules trapping them in the pores. This feature is enhanced in our product with an increase in complementing cations around the pores, reducing the maintenance and increasing long term effectiveness..

Aside from the filters, a few key features of the structure include the fact that the filters are removable (for maintenance), the connection screws can adjust between a radius of 65 mm to 120 mm through threaded mechanisms (refer to additional document) and that the three filters all removable require servicing after over a year, dependent on use, as compared to competitive products with much shorter spans.

Among the competition, the Green Mile separates itself with various technologies which are proprietary to the innovation. Firstly, it is the first implementation of zeolite in a filtering application, normally used in industrial processes. Zeolite has a strong tendency to capture specific particles based on its altered structure; in our case carbon dioxide is captured in the micropores within the material, which is then to be heated periodically (usually in 1-2 years) to remove the excess CO2. The density of zeolite used in the green mile allows for optimum performance for over a year, before the filter has to be serviced. Secondly, motor engines require a two way flow of air, and hence the exhaust is not only to expel air, rather it also acts as an inlet. Usually a structure like the Green Mile blocks this inlet with significantly less air flow rate, however, in the Green Mile there are three auxiliary tubes along with curved grooves which allow for additional air to flow into the engine. This helps compensate for the minimal reduction at the main exhaust allowing for an optimum function of the car.

We aim to protect the authenticity of the Green Mile with a patent on the product, protecting innovation with the configuration and type of filters which result in an optimum result by our high standards. A product which focuses on environmental concerns usually must be financially viable and convenient, hence, with our technologies we achieve both, adding value and providing customers with a smooth transition into a greener future.

How do we aim to validate our innovation, technology and process The Green Mile is an innovation which stems out of existing scientific research, innovation and applications. The filter configuration was first conceptualised using simple research and existing applications. Our synthetic filters draw from existing products which feature polyester and synthetic fibres, they have a ribbed structure similar to domestic air filters and are effective in trapping microparticles. The DPF (Diesel Particulate Filter) is an existing technology widely used in diesel engine exhausts, and we aim to subcontract the production of the same with purchase of our custom DPF to add to the Green Mile. Our design features a modification to adjust a third party DPF and that allows for a convenient and tested option to eliminate the most harmful emission of all, soot. Zeolite is a material which is often overlooked when it comes to air filters, hence, we looked at a variety of research studies and reports on the material before concluding on its application on the Green Mile. Its porous structure is heavily used in industrial processes and often eliminates gases, with knowledge of the same it was possible to find instances [1] where it is isolated and filtered for carbon dioxide, making it an ideal choice.

The design of the Green Mile was tested using online simulations, before focusing on developing a prototype. Using a scale CAD model, a fluid simulation on Blender with different particle densities in the air resulted in optimum results. Particles sized as CO2 molecules, small microparticles and soot particles were all seen to be eliminated around 80-85%. This allowed us to validate the design and prove its effectiveness.

Significant progress has been made in developing a prototype, the CAD model for our design is ready along with the chemical details related to zeolite and the synthetic filters. Procurement of a DPF along with 3d printing of the existing designs is under progress, after which it will be tested for performance, before entering a beta testing phase in the market.

Our business strategy and targets

The customers for this product would likely be individuals or organisations that own or operate vehicles and are concerned about reducing their carbon emissions, but are currently unable to due to limiting factors such as price, availability, lack of technical knowledge, lack of regional infrastructure etc.. Additionally, our customers would also include fleet operators

and transportation companies looking to meet increasingly strict emissions regulations being put in place by governments around the world. The size of the opportunity in this market would depend on factors such as the total number of vehicles in operation, the percentage of those vehicles that are eligible for the attachment, and the demand for products that help to reduce carbon emissions. The buyer or payer in this market could be the same as the customer, or it could be a third party such as a government agency or a company that is purchasing the attachments in bulk for their fleet on behalf of the vehicle operators. The industry ecosystem for this product would likely include manufacturers and distributors of the attachments, as well as service providers who can install and maintain the attachments on vehicles, providing crucial customer support. There could also be regulatory bodies and industry groups that set standards and guidelines for carbon emissions reduction in the transportation sector and utilise our attachment to do so.

How do we aim to eliminate our competition?

Carbon recapture systems along with activated charcoal membranes are used to trap the carbon from exhaust systems. However, these result in exorbitant maintenance fees and lead to economic problems. On the other hand, our innovation, although involves comparatively high first time purchasing expense, in the long run is cheaper than other systems in place. The filters being used to capture the pollutant particles are very durable and long lasting due to synthetic polymers being used in its manufacturing which are very difficult to break as they consist of long chain compounds. Moreover, synthetic polymers are more effective at removing the fine particles and are less likely to become clogged with debris. Since they are easy to clean, it results in lower maintenance costs. Only periodic cleaning (every two months) will be needed in order to ensure that the efficiency is maintained.

Other carbon recapture systems require storage space in order to be implemented, and complex setups which distort the very purpose of such environmental measures. Our innovation is a relatively small filter which can be manually attached to the car systems. This is an added benefit because along with simplicity and ease, it results in lower costs because additional labour is not required for attaching these filters to the car. In order to provide assistance to consumers, we will be providing a pamphlet with all the methods so that they face minimum difficulties.

The only disadvantage for our product is that it has first – time expenditure. However, in the long run, we will look for advancements in technology and take advantage of economies of scale which will make it easier for our product to be produced at a lower cost, something that will benefit our consumers.

Attracting the customers and increase market base

Our identification of the best initial or pilot customers will come through purposefully focusing on segments of the market that are interested in our product, a metric that we’ll judge through various factors such as demographics (environmentally speaking, millennials and gen-z are more environmentally conscious than previous generations) (3) and geographic location (sub-urban-urban in developing countries). Gathering feedback and implementing customers feedback will be crucial in our pilot stages. Our ultimate goal is to alternate between a distribution and licensing model, as we realise that our product has the potential to be used by millions of people. Beginning with distribution and transferring to a licensing model will allow us to gain access to scale and reach a larger amount of customers.

Model of the business: key revenues and costs and fundraising

Our key production costs would be the costs to buy synthetic materials such as polyester and synthetic fibres. Another major production cost would be to buy ceramic and metallic materials which will be used to make the Diesel Particulate Filters (DPFs). The cleansing of the DPF would require additional cost as the accumulated soot on its surface needs to be burned by specialist equipment.

There will be a cost involved to buy an adequate amount of zeolite that can be used to make the porous structures. Our products would be shipped to a wide range of markets including the domestic market as well as to other countries in the world which would include shipping costs but transporting quantities in bulk regularly will help us get a contract with shipping companies, reducing our costs drastically.

Our key revenues will be from individual consumers who will buy these filters as well as transactions with car resellers and production companies still working on petrol/diesel engines.

We will store the trapped polluted gases and transport these trapped gases to companies that can use it to make other products such as pen ink, chemicals like methanol being used in fuel cells, bricks, tiles etc. These include industries such as paper industry, real estate and architecture and the chemical industry. For eg: the company Gravity labs uses carbon soot to make tiles and paint. While this is one example, there are so many industries across the globe using this strategy for sustainability. By this trading, we will earn extra revenue.

Our overall cost would round up to approximately INR 3500 – 4000 per filter and we will charge around INR 4800 – 5000 per filter (approx $50 and 61$ respectively) in order to maintain profit margin and cover up the cost of production in the long term

In exchange for equity and/or filter supply, we will collect investments in our companies from well-established firms in the automobile industry. These firms would be willing to invest in our start-up because there is potential for significant returns and it will help add credibility to their corporation since they are engaging in processes related to a more sustainable environment. The funds we collect will be used to cover production costs for the subcontracting filters along with 3d printing and material sourcing.

Overall, we will require INR 5 Lakh for establishment and an additional 15 Lakhs to scale it up to a point where we will be able to address the potential needs of our pilot customers (An accumulative amount of around $25,000 USD). To get this funding, we’ll look to government subsidies, non-government organisations, local sponsors, friends and family connections and firms with whom we share a similar mission.